Differences between the standard kill methods inc gas migration

By heck that’s a long chapter title but this chapter will try and do what it says in the title – the Ronseal of chapter titles!

First up differences between the kill methods – the advantages and disadvantages – the pros and cons – the benefits and drawbacks. And remember we are comparing drillers to wait & weight when considering which one to choose for a particular well kill.

The advantages and disadvantages between the kill methods can be summarised as:

The big advantage of the drillers method is that you can start the circulation immediately. Now by immediately we do not mean as sson as you want. You have to wait for surface pressures to stabilise first but once they have stablised you can get into the kill. Summarising the benefits of starting immediately we get:

- Removes influx sooner

- Gives time to mix kill mud as influx circulated out

- Minimises fluids/cuttings settling in annulus – MOC

- Less chance of gas migration

Now if this is an advantage for the drillers it means it is a disadvantage for the wait & weight.

The other advantage of the drillers method is that it can require less calculations than wait & weight. Classic drillers only needs kill mud weight to be calculated – the rest can be done using gauges. Not ideal and certainly won’t help with identifying problems during the kill but… possible.

With wait & weight we need that pressure stepdown schedule which means more calculations. Now was that schedule overly difficult to work out? Of course not. However, that schedule is based on strokes, which is volume, and as we know pressure is affected by TVD not volume. Another assumption the stepdown schedule makes is that the well is vertical and in reality there will be some degree of angle in a modern well.

The wait & weight method has advantages over the drillers namely only one circulation and lower annular surface pressures. We saw the latter during the wait & weight kill – we have kill mud in the annulus when gas hits the choke which means our surface casing pressure will be lower than the equivalent point (gas at choke) on the drillers.

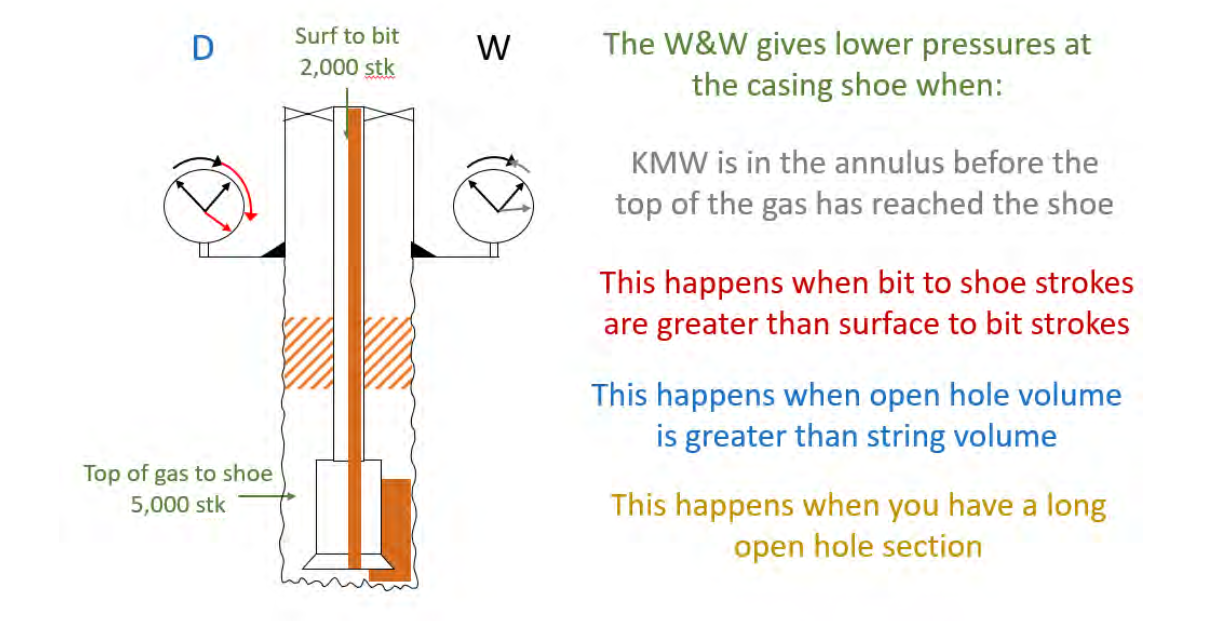

Sometimes there are lower pressures at the shoe. When? Well if you can get kill mud into the annulus before the top of the gas reaches the shoe then you will have increased the hydrostatic pressure in the annulus meaning lower pressure above the influx – ergo at the shoe.

One of the disadvantages of the wait & weight method is said to be the increased chance of gas migrating up the annulus while you are waiting on kill mud to be weighed up.

As gas migrates up a shut in well it will stay the same size (volume). Now Boyle said that if a volume of gas stays the same then the pressure inside the gas will also stay the same. The first version of IWCF formula 18 -

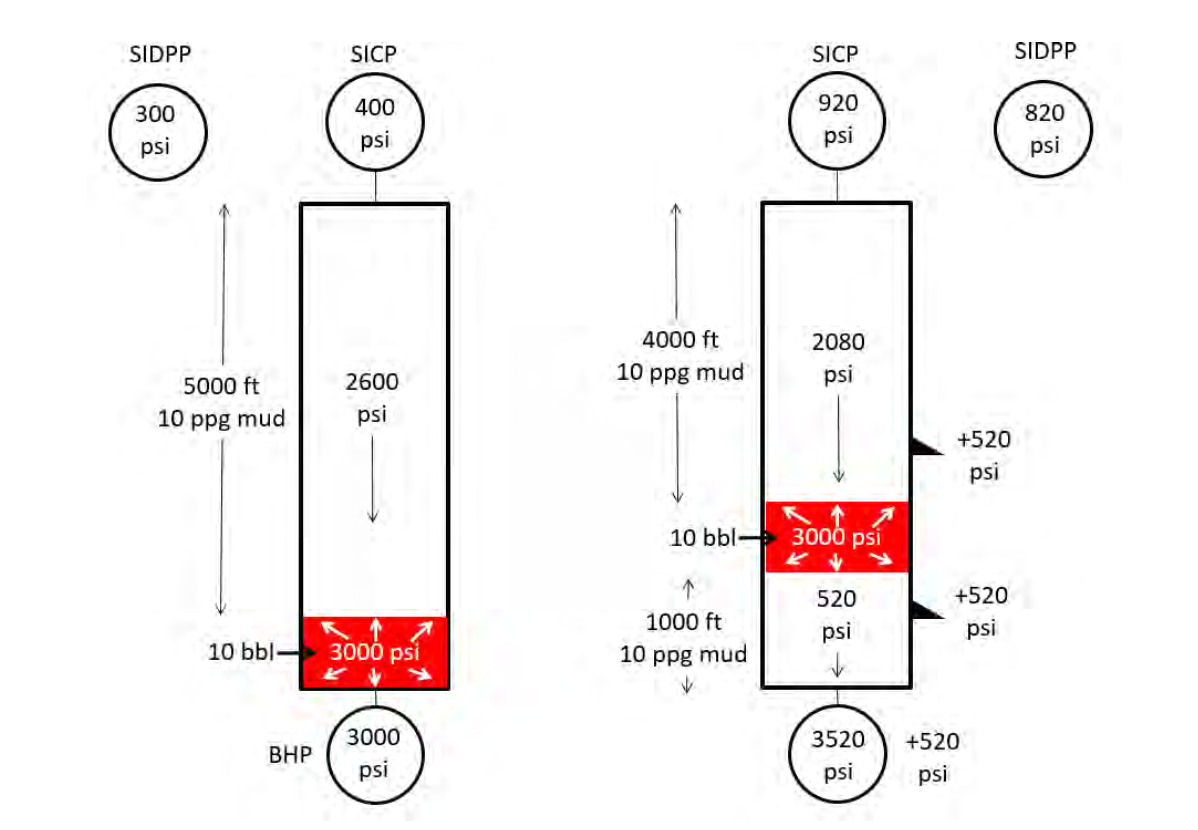

Gas bubble pressure stays the same as gas migrates up a shut in well. How do the other pressures in the well respond if gas migrates and no action is taken?

All other pressures in the well increase if gas migrates and no action is taken. BHP, casing pressure, drill pipe pressure and shoe pressure regardless of where the shoe is all increase is gas migrates and no action is taken.

The left hand well below is shut in stable – we are on balance. The right hand well shows how things change if gas migrates and no action is taken.

If gas is allowed to migrate uncontrolled to surface then all pressures in the well will increase and it is almost certain that you will exceed shoe fracture pressure. If the bit is below the influx then you could circulate the influx out using the drillers method.

If you cannot circulate but the bit is below the influx, and you can read SIDPP, then you could hold drill pipe pressure constant as gas migrates. The hydrostatic in the string will be constant so keep surface pressure constant and you keep BHP constant. You would have to open the choke to do this, which would allow the gas to expand in a controlled manner. More gas less mud in the annulus, less mud means less hydrostatic pressure so surface casing pressure would increase.

Holding drill pipe pressure constant keeps BHP constant so IDS applies in the annulus.

If gas migrates with no drill string communication, then you could use the volumetric method to bring the gas to surface. This requires accurate and careful monitoring of pressures and volumes. Your company will have detailed procedures to follow but it is relatively easy to do. It is a constant BHP method of well control so once again IDS applies in the annulus when using the volumetric method.

This week you may be asked what volume must be bled off to deal with gas migration – IWCF formula 25 and remember formation pressure is formula 4. You may also be asked to calculate how quickly the gas is migrating – formula 17 and be careful with the units – psi/hour!